As an Oregonian you may have seen hemp crops sprouting up around the state recently, but you may not know that Southern Oregon is home to the largest crop of hemp in the world harvested for something called CBG. Growing in the shadow of Table Rock in Central Point Oregon are almost 600 acres of genetically unique hemp. This hemp is being grown specifically for CBG, also known as 'the mother of all cannabinoids.' Recently the crew of That Oregon Life was invited to come see the harvest of this special hemp at Hemptown USA, and we're here to share that journey with you.

Wow, That's A Lot Of Hemp

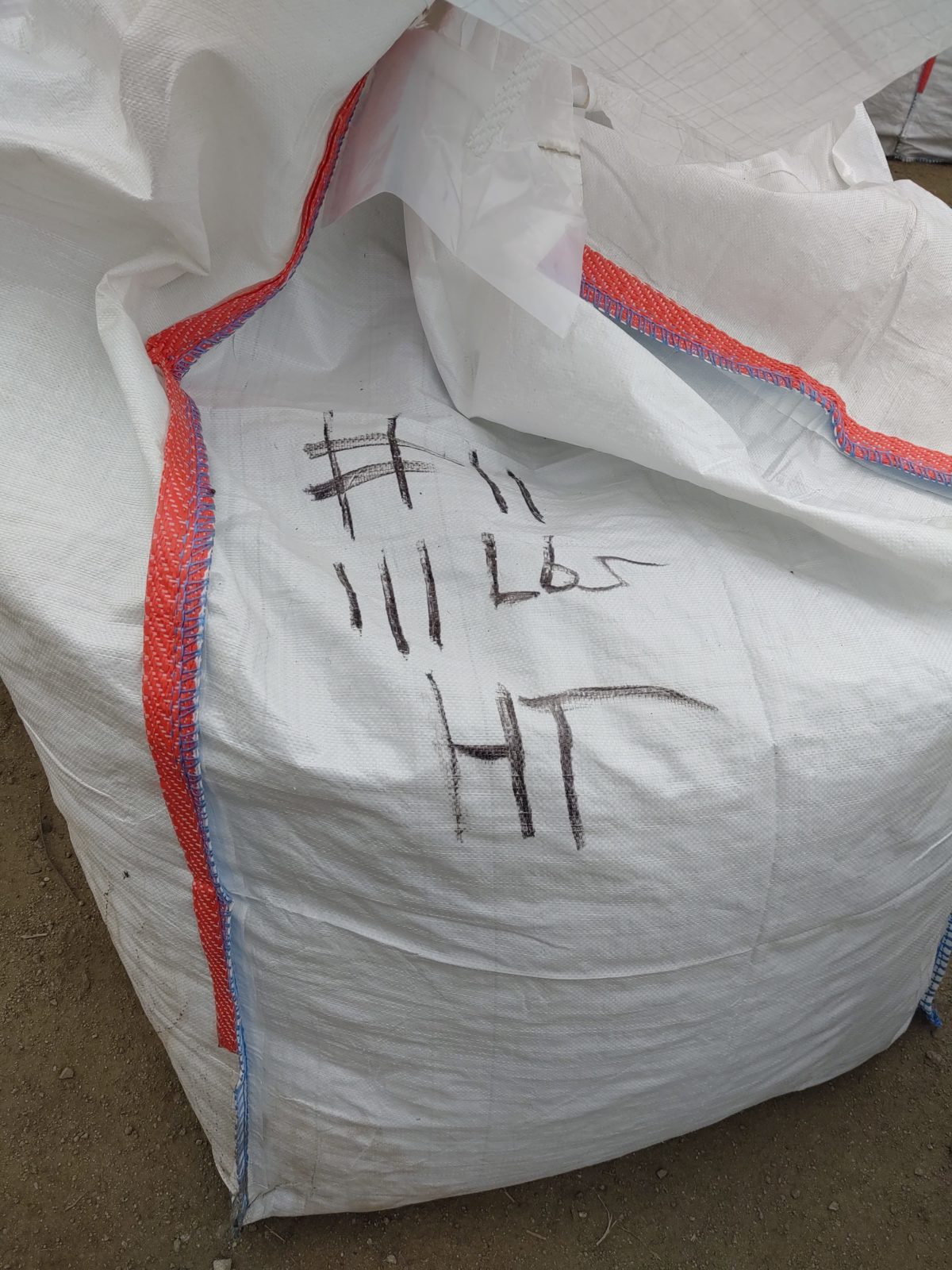

As we drove up to the farm, all we could think was, 'Wow, that's a lot of hemp.' Fields and fields of hemp grown across several farms with the scenic Table Rock as a back drop. And when we were taken to the drying rooms, we thought, 'That's a lot of hemp.' When we saw rows of 110 pound bags outside the warehouse, we thought, 'That's a lot of hemp.' On every stop of our tour through the Central Point Hemptown USA operation, we were even more in awe than we had been before. We weren't just in awe of all the hemp, but of the ingenuity of how it's being grown and harvested, because harvesting hemp for CBG on this grand of a scale is a first, and new processes have to be invented to make it happen. It's even more impressive that this is an Oregon grown company that's putting Oregonians in the area to work.

Last year Hemptown USA was only growing 100 acres in Southern Oregon, but they expanded to 560 acres this year. Central Point is an ideal location as it's at the Northern end of the famous 'Emerald Triangle', where conditions are just right to grow the perfect hemp plant.

The harvest at Hemptown USA began on September 10th, and finished mid October. The crew at Hemptown had to get as much harvested as they could before the rain moved in for the season.

A hemp plant ready to be harvested at Hemptown USA in Central Point Oregon. Photo by Danielle Denham ThePDXPhotographer

Harvesting Hemp Isn't As Easy As It Sounds

Each day there are hundreds of pounds of finished dry flower being sent from Hemptown USA to make high quality CBG oil. The top flower is the most important part of the plant as it makes the highest quality oil, so the first step of harvesting is for workers to hand pick the best part.

Keith Stride CMO at Hemptown USA inspects drying hemp in a huge drying room in Central Point. Photo by Aubry Bracco.

Once removed, the top flowers are cut by hand and hung to dry in long rows up to 25 feet high. During our tour, there was so much hemp harvested that day that workers were busy hanging up hemp to dry in the greenhouse, where the process started earlier this year with seedlings.

Hemp hanging to dry in the greenhouse. Photo by Danielle Denham ThePDXPhotographer

Walking through the tall rows of drying hemp was like entering another world. When you get deep into the rows the light is blotted out and the air grows thick with humidity. Warm air is pumped into the room to help with the drying process.

Hemp is hung to dry in long rows that dwarf you as you walk through them. Photo by Jessica Tomlinson

The next step for the top flower after being picked and dried is being hand "bucked" to remove stems and leaves.

A worker cuts a flower from a dried hemp plant. Photo by Danielle Denham ThePDXPhotographer

For further refinement, the buds are then put through a machine that removes everything else, leaving only the coveted emerald nugget.

Top flowers go through a machine designed to remove all but the flower. Photo by Danielle Denham ThePDXPhotographer.

The flower comes out of the end of the machine perfect and ready to be sent away to use for oil or to be sold for other products. After the top flower is picked a combine churns up the rest of the plant to create hemp bio-mass.

Because there was so much hemp to harvest this year, Hemptown USA built huge drying silos.

These silos are used to dry the harvested hemp. Photo by Jessica Tomlinson

Inside the silos there are two levels.

The lower level of a drying silo where hot is pumped in to help dry the freshly harvested hemp. Photo by Jessica Tomlinson

Still under construction in the next photo you can see one of the massive fans used to pump hot air into the drying silo.

A massive fan blows hot air into this silo to help dry freshly harvested hemp. Photo by Jessica Tomlinson

After the plant is dry other flowers are cut off the plant by hand and the plant is separated into it's various parts to be sent off to be made into CBG oil. Bags weighing over 100 pounds were lined up outside, full of dried flowers ready to be sent to make high quality oil.

Bags of dried flowers, ready to be sent to make CBG oil or be sold for other products. Photo by Jessica Tomlinson

Because of how much hemp was being grown, there just wasn't enough time to harvest it all by hand, so a combine processed hundreds of acres of hemp, turning it into biomass, flower and all, to go into CBG oil production.

On the day we visited Hemptown USA, about 250 people were hard at work manually harvesting flowers, transporting hemp, working heavy machinery and hanging hemp to dry. Between the enormity of the operation and the beautiful backdrop of Central Point, we were all in awe. For those that may be wondering, the smell wasn't bad. There was a scent, but it didn't smell like marijuana. Throughout the tour, the air smelled like mint with a hint of cannabis.

A truck transports hand cut hemp to be dried. By Danielle Denham ThePDXPhotographer

What Is CBG And Why Is It So Important?

Photo by Danielle Denham ThePDXPhotographer

Hemptown USA is currently the largest grower on earth of hemp that is genetically special to produce CBG. What is CBG? CBG, short for Cannabigerol is one of a family of over 100 molecules known as cannabinoids that are produced by cannabis. What makes CBG special is that it's the origin of all other cannabinoids. Without CBG you wouldn't have THC or CBD.

"CBG is historically expensive to grow and only harvested in small amounts when it's young and before it turns into THC and CBD," said Keith Stride CMO for Hemptown USA. Keith was our guide through the tour and was a wealth of information. "The seeds are designed to grow to full maturity without producing THC," said Stride. These genetically special hemp seeds can yield up to 15% CBG and as little as 0.001% THC, versus normal hemp which grows CBG in very low concentrations.

A 100+ pound bag of hemp flowers are ready to be sent to make high quality CBG oil. Photo by Danielle Denham ThePDXPhotographer

CBG is being studied for a variety of health and wellness applications. It's been found to be antibacterial and antimicrobial, and is absorbed well through the skin like CBD. The bioavailability is even higher if ingested. Hemptown USA has put together a CBG White Paper which you can look at here. This paper brings together all the current research on CBG and its uses.

"I think people are excited for the potential of CBG," said Stride. "You'll start to see it in topicals soon."

Check out this video about their growing season this year:

If you'd like to learn more about Hemptown USA, check out our previous article here, or visit their website. You can also get up to date information on the Hemptown USA Facebook page.